In the U.S., electric buses are transforming the transportation industry. Electric buses are powered by electricity instead of conventional fuels, which makes them an environmentally friendly alternative.

In this blog, we will explore the advantages of electric buses and their impact on the environment.

Understanding Electric Buses Before we jump into the details, let’s understand what is an electric bus.

An electric bus can be defined as a type of electric vehicle, running, with the use of zero-emissions, and with the use of electricity, as its name states. These buses provide sustainable mobility solutions because they decrease air and noise pollution, dependence on fossil fuels, and greenhouse gas emissions.

Advantages of Electric Buses One of the most important advantages of electric buses is their reduced impact on the environment. Majority of the traditional buses run on diesel, these emit harmful pollutants into the air, making it polluted. These pollutants can cause respiratory illnesses and various other health problems.

Whereas, electric buses do not emit any pollutants. They run by batteries, that are charged using an external power source, for example, a charging station. Hence, electric buses produce zero emissions, thus help in improving the air quality.

Another advantage of electric buses is the reduction of noise pollution. The traditional buses are loud, mainly when accelerating. Whereas, electric buses are significantly silent, and offer the passengers a pleasant riding experience.

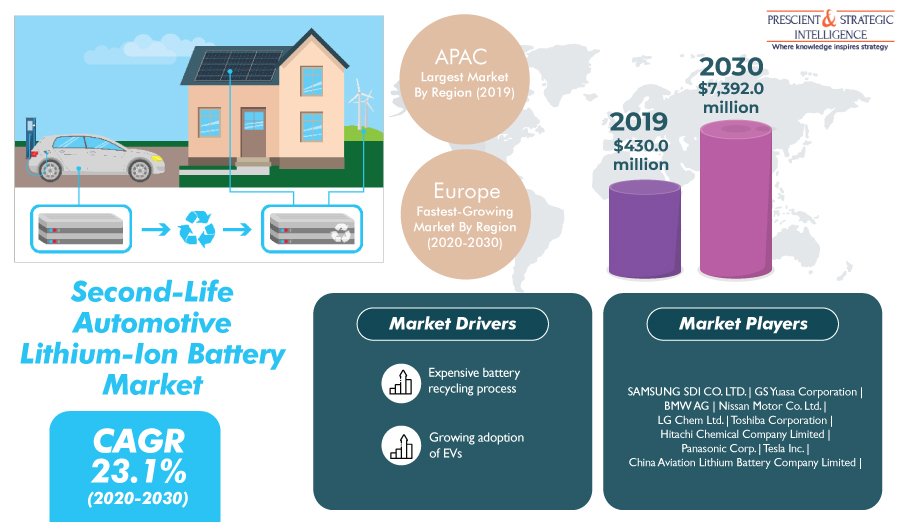

Lithium-ion Battery is Used the Most in these Buses Lithium-ion battery is the most used battery for electric buses, this is a rechargeable battery and offers benefits such as a long-life cycle, low maintenance costs, low weight, zero-carbon emission, and high energy concentration. Thus, ensuring safety and extended life for an electric bus.

Electric School Bus Initiative and its Importance

The goal of this initiative is to build a momentum toward using electric buses in every school in the U.S. by 2030.

Electric school buses are important because, most of the school buses run on diesel, which emits harmful pollutants, and much exposure to these pollutants can cause asthma and respiratory issues, in children.