While medical adhesives cover a wide spectrum of fabrication materials, they are primarily made of biological or synthetic formulations. Medical adhesives are frequently used for surgical operations and device bonding. A variety of adhesives, some of which are disposable, are used in medical equipment, sometimes more than once.

High heat ranges may be tolerated by high-strength bonding adhesives; some of them are appropriate for electronic devices.While medical adhesives cover a wide spectrum of fabrication materials, they are primarily made of biological or synthetic formulations. Medical adhesives are frequently used for surgical operations and device bonding. A variety of adhesives, some of which are disposable, are used in medical equipment, sometimes more than once. High heat ranges may be tolerated by high-strength bonding adhesives; some of them are appropriate for electronic devices.

Moreover, adhesives are excellent for skin and suture applications, others are perfect for attaching a wide range of substrate surfaces, such as metals, plastics, and rubbers. Medical-grade adhesives can be divided into one- or two-part epoxy systems, with each having a unique curing response. Medical adhesives are frequently used in applications such as labeling electrodes, implanted devices, catheters, and surgical tools.

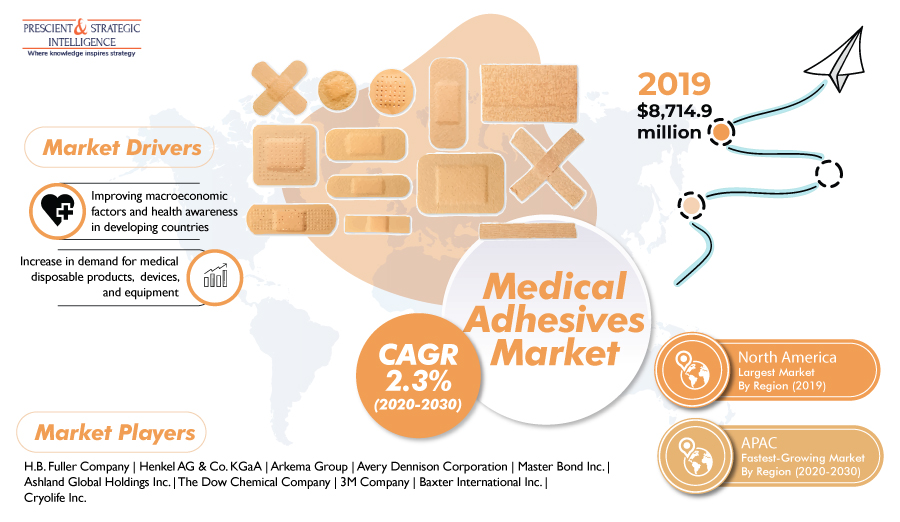

The demand for medical adhesives was significantly impacted by COVID-19, particularly in China, the U.S., Spain, Germany, Italy, and other western European nations. Nevertheless, the demand for medical adhesives is benefiting from the surge in demand for personal protective equipment, masks, blood and saline tubes, and syringes.

Due to the rising number of patients needing long-term chronic care therapy, procedures, and drug delivery, there is an increased need for disposable medical equipment, supplies, and other items. The demand for medical devices has increased as a result of healthcare organizations, such as outpatient facilities and hospitals, placing an increased emphasis on infection control and safety measures.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/medical-adhesives-market-report/report-sample

Advantages Adhesives for Medical Devices

There are several alternatives for pressure-sensitive, non-structural, and structural adhesives available today. There are several benefits to employing adhesives rather than mechanical fasteners.

• For prolonged therapeutic usage, medical adhesives are light, plush, and pleasant enough

• Medical foam tapes are made with strong materials in appealing colors

• In comparison to films and nonwoven tapes, polyethylene foam tape is soft, pleasant, and reasonably priced when applied close to the skin

Adhesives provide extra advantages in the medical sector. Medical adhesives are already built to comply with FDA regulations for labeling, digital tracking, and durability rub testing. In addition, certain adhesives have UL certifications and are approved for use with particular printing processes and inks. These characteristics significantly reduce the amount of guessing involved in choosing materials that meet your needs and industry standards.