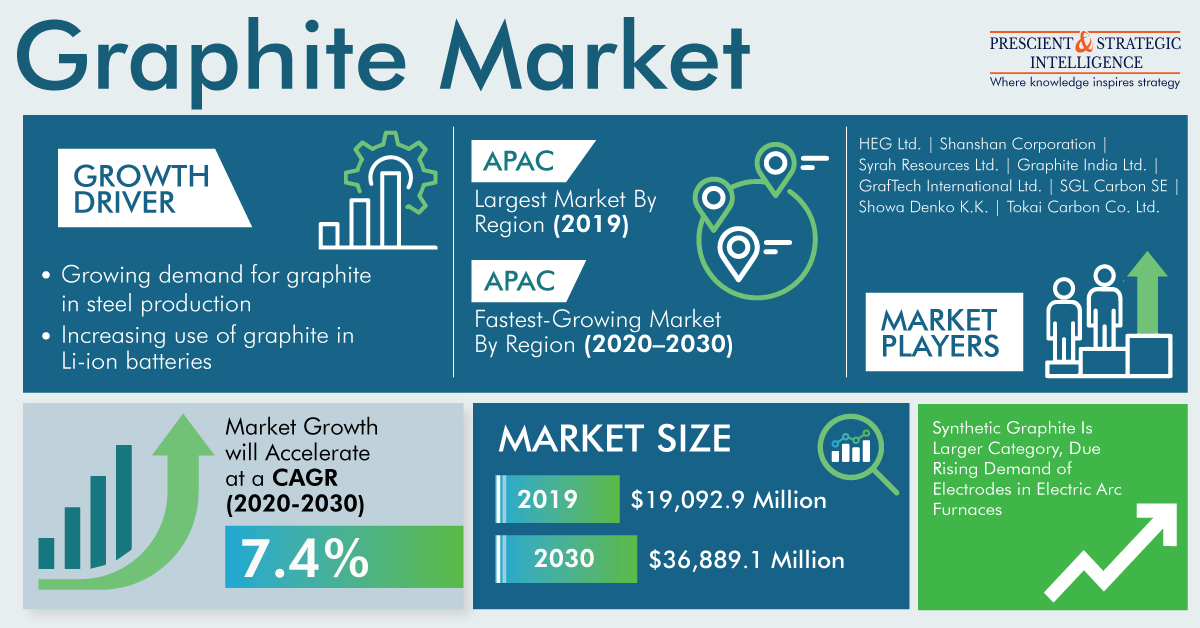

A number of factors, such as the expanding electronics sector, burgeoning steel production, and soaring lithium-ion (Li-ion) battery demand, are expected to fuel the graphite market at a CAGR of 7.4% during the forecast period (2020–2030). According to P&S Intelligence, the market revenue will rise from $19,092.9 million in 2019 to $36,889.1 million by 2030. In recent years, the increasing usage of graphite in pebble-bed nuclear reactors, for generating electricity from uranium fuel, has become a prominent market trend.

At present, the graphite market is fragmented in nature with the presence of numerous industry players, such as Syrah Resources Ltd., SGL Carbon SE, Graphite India Ltd., Shanshan Corporation, HEG Ltd., Showa Denko K.K., Tokai Carbon Co. Ltd., and GrafTech International Ltd. Currently, these players are merging with and acquiring other companies to stay ahead of their competitors. For instance, in December 2019, Showa Denko K.K. completed the acquisition of Hitachi Chemical Ltd. for $8.8 billion. This acquisition aimed at consolidating the position of the former as a leading supplier of graphite to manufacturers of Li-ion batteries.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/graphite-market/report-sample

Furthermore, the application segment of the graphite market is categorized into lubricants, electrodes, refractories, batteries, foundries, graphite shapes, and friction products. Among these, the batteries category is expected to demonstrate the fastest growth throughout the forecast period. This will be due to the surging production of electric vehicles (EVs) and hybrid electric vehicles (HEVs), especially in Europe and North America. Moreover, the booming demand for high-drain electronics, due to the soaring disposable income of people and escalating consumer expenditure, will also support the growth of the market in this category.

Thus, the rising crude steel production and the escalating demand for Li-ion batteries will boost the demand for graphite, worldwide, in the coming years.