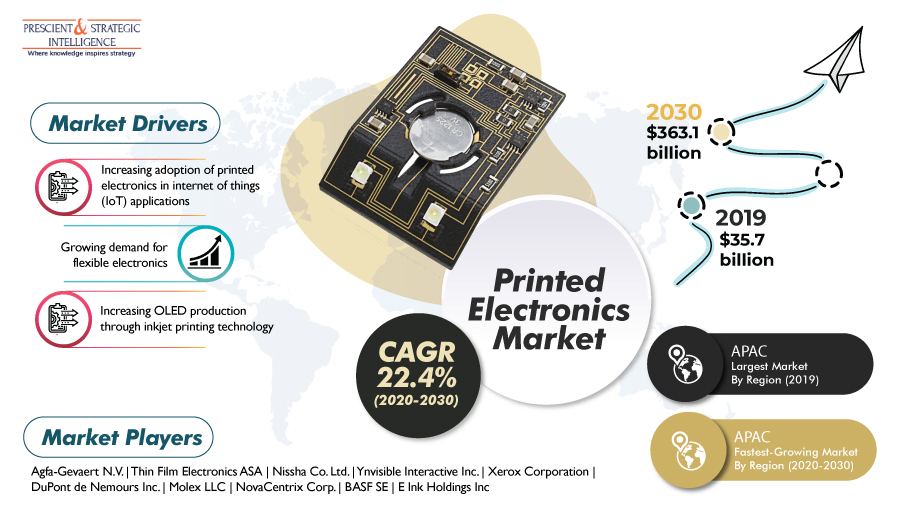

Electronics are manufactured with the help of silicon or other semiconductor materials for a fairly long time. The process is complex as well as time-consuming. However notable miniaturization, high-performance and low power is attained. Instead, making flexible silicon-based electronics is not that easy either.

For addressing this issue, a new tech has arisen, the printed electronics. This blog will provide some valuable info on this tech, concentrating on how it can be used in practical applications.

What on Earth are Printed Electronics

Talking of printed electronics tech, it is a novel way to produce electronics, with the use of standard graphic arts printing procedures, for example screen printing, flexography and inkjet printing, numerous electronic devices and circuits can be fabricated on unconventional substrates. Nearly any material can be put to use for this purpose, be it plastic, paper, and textiles.

These sorts of next-gen electronics can be ultra-thin, stretchable, flexible. Furthermore, printed electronics make use of a simple and cost-efficient low-temperature manufacturing procedure and are compatible with automated mass production printing by the roll-to-roll principle.

Creation of Hybrid Electronics

It will be rally tough for printed electronics to compete with conventional silicon-based electronics in terms of reliability, performance, and capability to handle intricate designs. But the possibility of inserting electronics in any object and that too at a low cost seems an enticing prospect. So, the printed electronics are seen as a complementary tech for the conventional electronics.

This understanding inspires the formation of hybrid electronics. These can have the best qualities of the two. Such a hybrid system comprises a single or numerous silicon ICs for computational power and wireless communications, and sensors, actuators and possibly display manufactured with the printed electronics tech. The system can moreover be integrated on a flexible substrate all together or split in a flexible or rigid part.

What are the Applications of Printed Technology?

It is because of all the unique characteristics; printed electronics can bring about new possibilities for numerous attractive applications that are either not practicable or not a perfect for the silicon-based electronics. Printed sensors are perhaps the most popular in the printed electronics and various sensor can be manufactured in all shapes and sizes on thin foils. Strain, force, humidity and gas sensors are some instances of the sensors.

Useful for IoT

Internet-of-Things products in healthcare, retail, wearables, industrial and consumer applications are remarkably benefitted by with the use of printed sensors.

An example of this is a fall detection system, equipped with sensors embedded under the floor in housing units for aged people and assisted living facilities. This system is able to monitor the position of the people and movements in a room and sense instances when the help of the caregivers is required on an urgent basis

Coming to a Conclusion

It is because of the growing consumer electronics industry all over the world, the demand for printed electronics is on the rise. This trend will continue in the future as well, and the total value will reach USD 42.4 billion, by the end of this decade.