Specialty chemicals, also known as performance chemicals, are a category of chemicals that are produced for specific applications. These chemicals are designed to meet precise performance requirements and are often produced in small quantities.

These chemicals are adopted in different industries, such as agriculture, pharmaceutical, plastics & composites, automotive, electronics, and personal care. Specialty chemicals, also known as performance chemicals, are a category of chemicals that are produced for specific applications.

These chemicals are designed to meet precise performance requirements and are often produced in small quantities. These chemicals are adopted in different industries, such as agriculture, pharmaceutical, plastics & composites, automotive, electronics, and personal care.

The global industry of specialty chemicals is expected to reach USD 980,423.7 million by the end of this decade. Uses of Specialty Chemical Specialty chemicals can be used as ingredients to improve performance of the products or processes in numerous industries.

Here are some of the industries these chemicals are used heavily.

Pharmaceutical Industry

Specialty chemicals are also used as raw or intermediates materials throughout all stages of pharmaceutical manufacturing to create non-reactive, colorless, and odorless drug carriers, to purify raw materials, to improve characteristics, for instance, water solubility, and to assist in producing the final form of the medication, for example, capsules or tablets.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/specialty-chemicals-market/report-sample

Types of Specialty Chemicals

There are numerous types of specialty chemicals based on their functions or industries’ applications. One of the most used types of specialty chemicals is agrochemicals.

Some other types of specialty chemicals are:

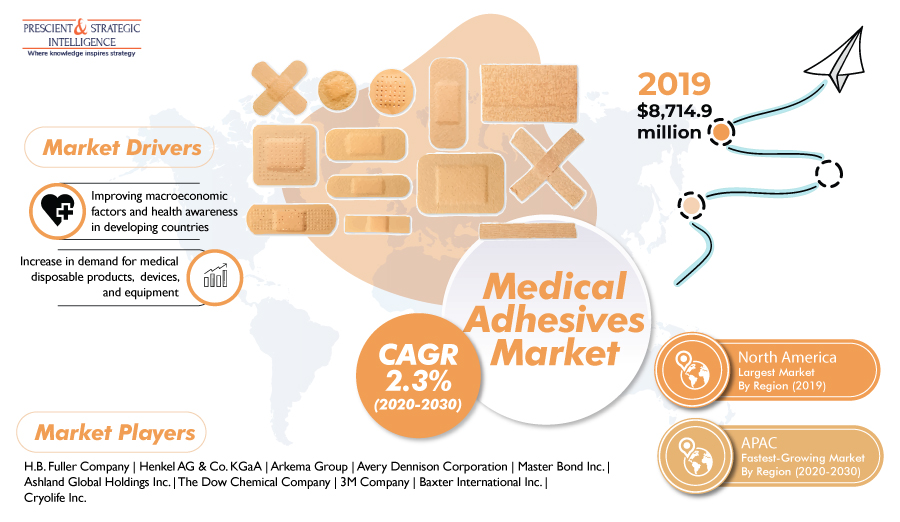

• Adhesives and sealants: These chemicals are adopted to bond materials together and offer leak-proof sealing in numerous applications, for instance in packaging, automotive, and construction industries.

• Food additives: These chemicals are used as ingredients added to food products to improve their texture, taste, preservation, or appearance.

• Polymers: These chemicals are used in manufacturing elastomers, resins, and plastics.

Due to the diversified application of specialty chemicals in numerous industries and the increasing requirement of these chemicals in emerging economies, such as China and India, the demand for specialty chemicals will continue to rise in the years to come.