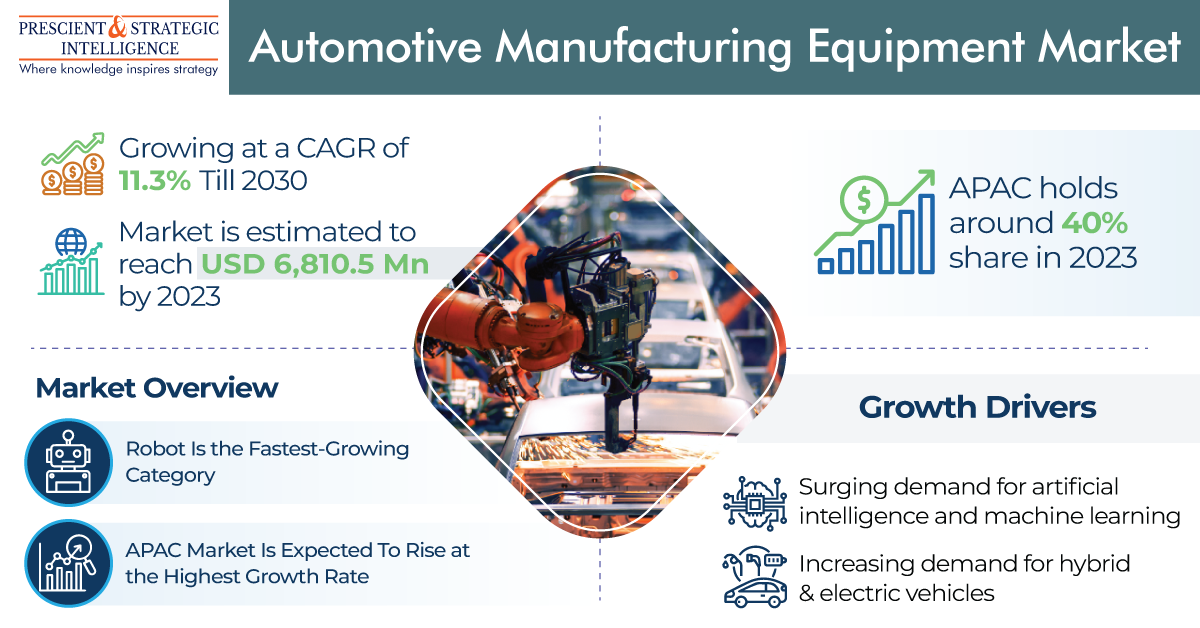

The automotive manufacturing equipment market is around USD 6,810.5 million in 2023, and it will advance at a rate of 11.3% by the end of this decade, to touch USD 14,260.4 million by 2030.

This is credited to the fast-growing vehicle requirement and the growing acceptance of robotics and automation technologies for coping with the booming automotive requirement.

In the tech world, industries are shifting from conformist methods to cutting-edge production technologies, such as ML and AI. These technologies are there in the entire automotive industry, helping it to meet the requirement for vehicles on time.

These similarly help control systems and communicate with other apparatus so there is no effect on the work. Numerous organizations have accepted AI and advanced technologies, because of their several benefits, to advance quality, help meet the requirement on time, boost the supply chain, and operate functions easily.

The robot category will have the fastest growth, about 12.5%, in the near future. In the vehicle manufacturing sector, robots are the most significant part of manufacturing processes because they work in the best way with enhanced task management. Also, robots can continually do tasks with quality, high consistency, less error rate, and greater productivity.

The automatic category will grow at a higher rate in the automotive manufacturing equipment market, of about 11.5%, in the years to come. In the automobile industry, automatic technologies are accepted extensively because of their efficiency of work, high quality, and supreme productivity.

Similarly, automatic manufacturing technologies can achieve tasks without the participation of humans, as a result of which the production cost is reduced with supreme production output. Additionally, these technologies support in making the production facilities more advanced and efficient.

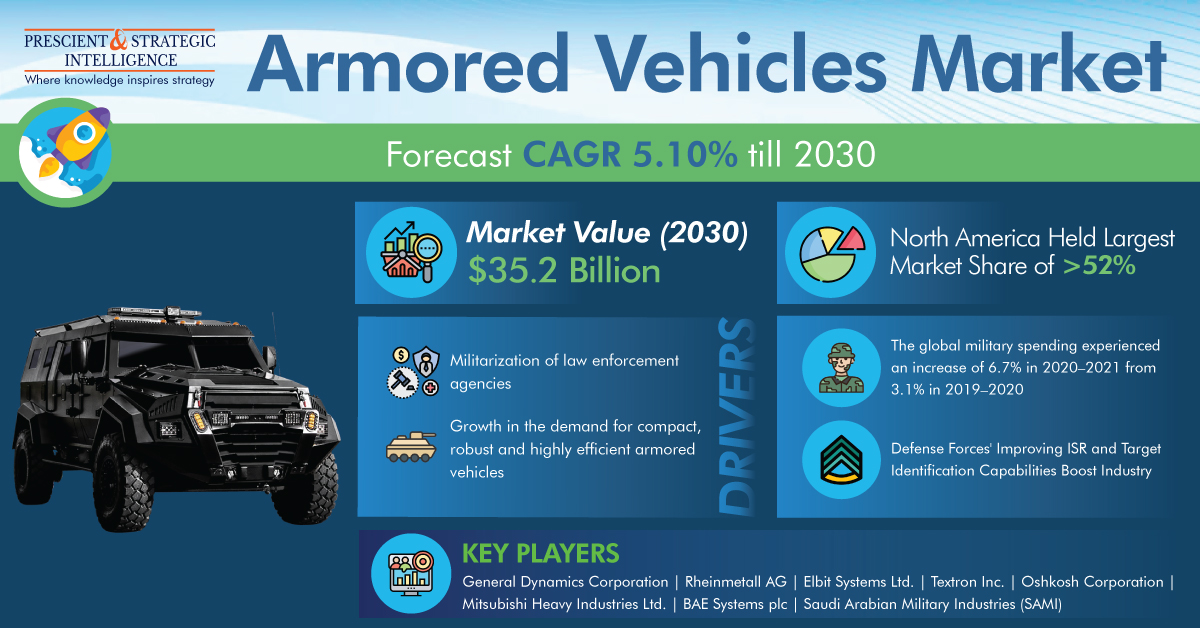

armored vehicles market, military defense, security solutions, military technology, defense industry, armored personnel carriers, defense procurement, homeland security, ballistic protection, vehicle armoring, military vehicles, tactical defense

armored vehicles market, military defense, security solutions, military technology, defense industry, armored personnel carriers, defense procurement, homeland security, ballistic protection, vehicle armoring, military vehicles, tactical defense