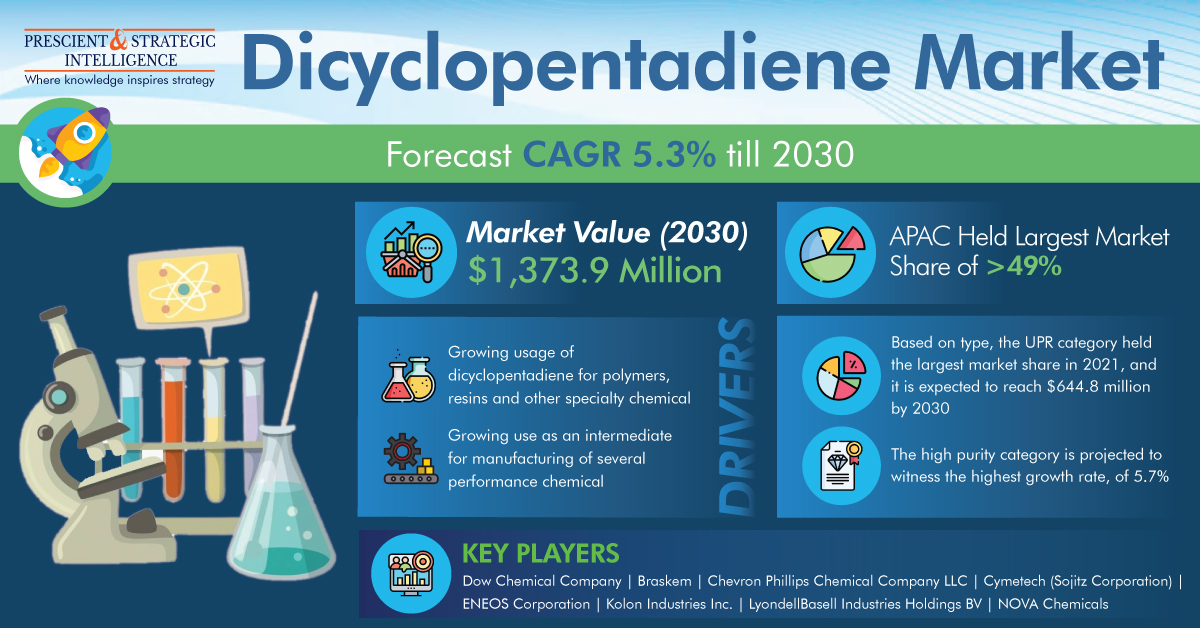

The dicyclopentadiene market will touch USD 1,373.9 million, propelling at a 5.3% compound annual growth rate, by 2030.

The growth of the industry is mainly because of the increasing utilization of dicyclopentadiene for resins, polymers, and various other specialty chemicals. Furthermore, because of its extremely reactive nature, it can be utilized as an intermediate for the production of various performance chemicals utilized in packaging, automotive & marine, and building & construction industries.

In recent years, the UPR category, based on type, accounted for the largest industry share, and it will generate USD 644.8 million, advancing at approximately 5.4% CAGR, by 2030.

The UPR grade is a key element in the production of coatings, varnishes, paints, rubber, pesticides, adhesives, insecticides, and other products. This is attributed to the fact that it comprises lesser trimers and co-dimers, displays enhance color characteristics compared to other resins and has better functional and mechanical properties.

Whereas, the high purity category will observe the highest growth, of 5.7% in the years to come. This is because of the increasing requirement for specialty & fine chemicals.

The hydrocarbon resins category, based on application, will observe the fastest dicyclopentadiene market growth, of approximately 5.7%, in the years to come. The main applications of hydrocarbon resins are labels, hot melts, and PSA tapes. These intermediates are also utilized as a tackifier during the production of products such as printing inks, paints, adhesives, rubbers, and coatings.

Based on industry, the building & construction category accounted for the largest share, in the past few years. Furthermore, it will generate a revenue of USD 328.7 million, propelling at a 5.3% CAGR, by 2030.

In the past, APAC accounted for the largest dicyclopentadiene industry share, and it will advance at a 5.4% compound annual growth rate throughout this decade. This is because of the increasing requirement for this chemical in the plastic and resin sector in this continent.