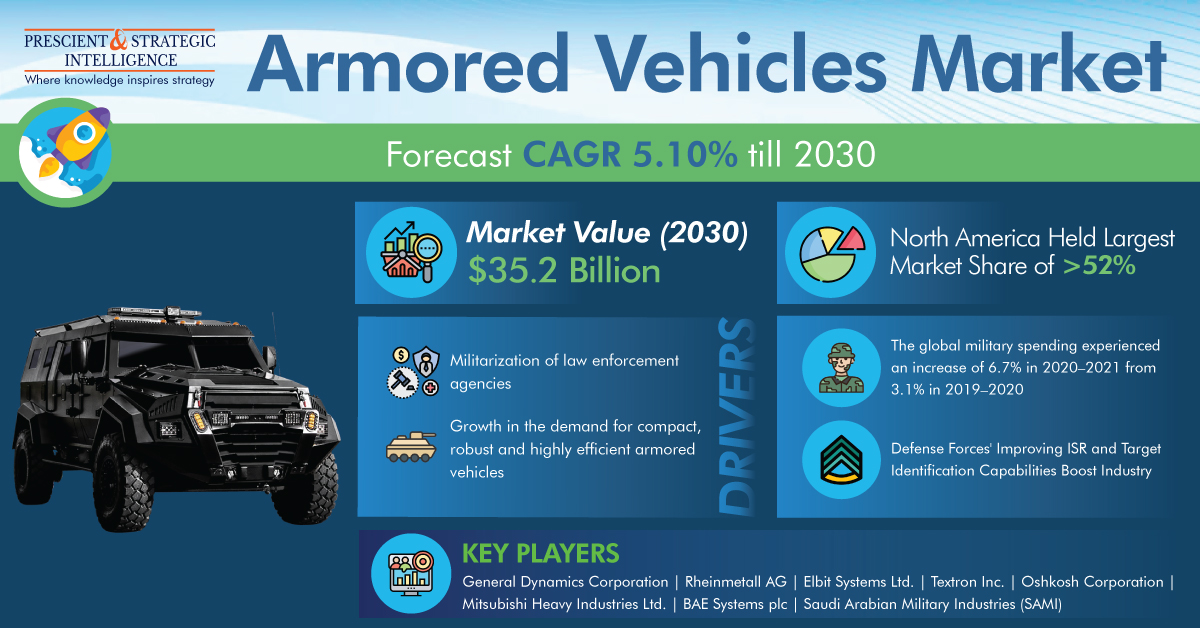

The armored vehicles market will reach USD 35.2 billion, growing at a rate of 5.1%, by 2030 as per a report by P&S Intelligence. This can be credited to the rising cross-border disputes, increasing demand for robust, compact, and highly effective armored vehicles, the increasing defense expenses of several nations, and the militarization of law enforcement agencies.

Furthermore, the high expenditure on R&D by key industries and collaborations of government and private organizations to produce highly innovative solutions for defense are boosting industry growth.

armored vehicles market, military defense, security solutions, military technology, defense industry, armored personnel carriers, defense procurement, homeland security, ballistic protection, vehicle armoring, military vehicles, tactical defense

armored vehicles market, military defense, security solutions, military technology, defense industry, armored personnel carriers, defense procurement, homeland security, ballistic protection, vehicle armoring, military vehicles, tactical defense

Unmanned armored ground vehicles are expected to witness the fastest growth in the armored vehicles market, during the forecast period. This is credited to the increasing demand for these vehicles due to their crucial role in assisting logistic operations onshore and supporting terrestrial combat.

Combat vehicles generated the highest revenue in recent years, and this trend will continue in the future as well. This is because of the rising demand for light-protected vehicles and armored personal carriers.

Global military spending has increased significantly in the past few years. Due to internal and external security threats, conflicts between nations, technological advancement in defense, rising terrorism activities, and various border security issues.

Wheeled armored vehicles held the larger revenue share in recent years, and they will witness faster growth during the forecast period. These are gaining popularity because of their advanced combat capabilities, lighter weight, and better mobility.

In addition, the increasing incidence of terrorist attacks in urban areas has boosted the requirement for armored vehicles.

It is crucial for defense forces to carry out better monitoring of land and naval borders. As robots can perform better in border surveillance, they can substitute humans in some situations. These robots can effectively patrol national borders and transmit real-time information. Such vehicles are provided with armor to enhance durability.

The defense category held a larger share in recent years, and it will remain larger in the years to come. This is because of the increasing usage of armored vehicles such as APCs, LPVs, IFVs, MBTs, MRAP, and the focus on the safe deployment of soldiers to battlefields and risky areas.

North America held the largest share,of over 52%, and it is expected to continue like this. This is because of the existence of numerous equipment and military machinery manufacturers, the collaboration between government and industries to develop advanced vehicles, and the high rate of advanced technology adoption.