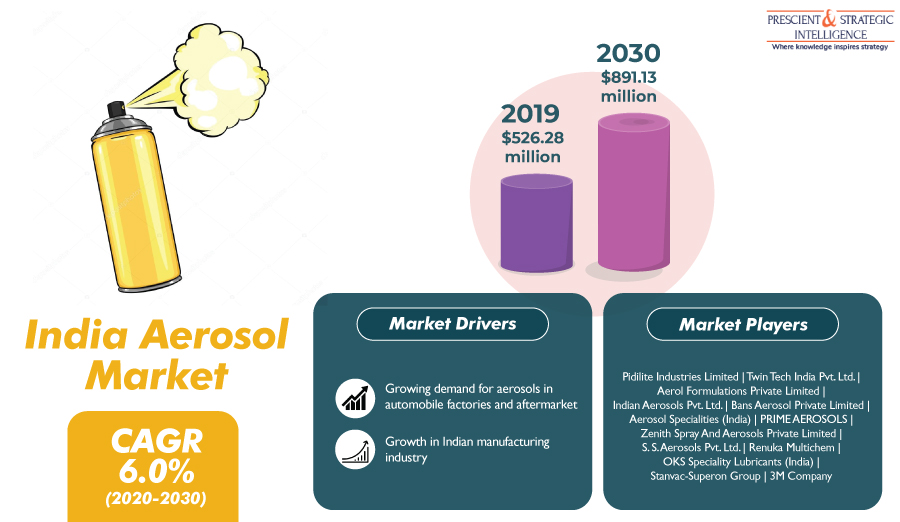

The major drivers for the India aerosol market to $891.13 million by 2030 will be the skyrocketing investments in the research and development in the production units, extensive government support, and the surging need for aerosols in numerous industries including manufacturing and automotive industries. The outbreak of COVID-19 ruptured the entire logistical network of this market because of the temporarily shutting down of production units as lockdown was imposed in India. Furthermore, the lowering trading activities exerted a halt on the sales of these materials.

Within the application segment, the personal care category holds the biggest India aerosol market share, and it will show this trend in the coming years as well. This can be ascribed to the snowballing demand for body care products (sun protection products, self-tanning & skin-whitening lotions, and hydrating creams), personal care products (cream foundation, gel toothpaste, foams & gels, and deodorants & antiperspirants), and hair care products (shampoos, hair shines, hair mousses, and hairsprays & styling sprays). Furthermore, the surging inclination toward personal hygiene care is laying the firm foundations for the category’s growth.

Moreover, antiperspirants/deodorants rule the personal care category in the India aerosol market because of the growing awareness of body odor problems and personal hygiene. The spray paints category will potentially grow in the coming years because of the economic viability and versatility of spray paints. There is a rising inclination for this category in comparison to the plastic, wooden, and metallic applications. There is a rising utilization to re-spray or restore aviation and automotive components. Additionally, there is a surging application of spray paints to fill the scratches in industrial machinery.

Similarly, the India aerosol market was ruled by air freshener products in the past few years within the residential product type. This can be primarily attributed to the skyrocketing demand for the refreshing ambiance in cars and homes that is free of undesirable odors. Apart from creating a refreshing environment, it also enlightens the mood of people. The absence of volatile organic compounds and the increasing inclination toward air hygiene will augment growth in the market.

When segmented on the distribution channel, the India aerosol market is categorized into hypermarkets/supermarkets, convenience/department stores, and others. Sales via hypermarkets/supermarkets are predicted to advance at the swiftest CAGR in the coming years. This is because of the fast modernization in the retail sector, which in turn, will increase the count of the number of supermarkets and hypermarkets, particularly in metropolitan cities. All of this will propel growth in the market.